- Home

- Sustainability

Sustainability

Join us in our mission to recycle, reuse, and regenerate — because a sustainable future starts with responsible choices today.

Keeping sustainability at the core, we, at Alliance give solutions for sustainability by reducing carbon footprints in production. With rising demands in eco friendly products, we are committed to create products from recycled PET waste to make world a better place with every step forward.

Our Contribution to a Better Earth

Reduce CO₂ Emission

RPET polyester products have a 75% lower carbon footprint than conventional polyester products, helping cut down greenhouse gases significantly.

No Crude Required

RPET yarn eliminates the need for crude oil—a finite resource—making production more sustainable and resource-efficient.

Less Water Usage

Manufacturing recycled polyester consumes up to 20% less water compared to virgin alternatives, conserving a vital resource.

Energy Saving

RPET production requires 60% less energy than virgin fibre, making it an energy-efficient and eco-conscious alternative.

Towards Zero Waste

Only 7% of plastic was recycled in 2012. We work toward increasing this rate with innovative recycling practices.

Fresh Landfills

Recycling one ton of PET saves around 5.7 square meters of landfill space, reducing environmental pressure and land pollution.

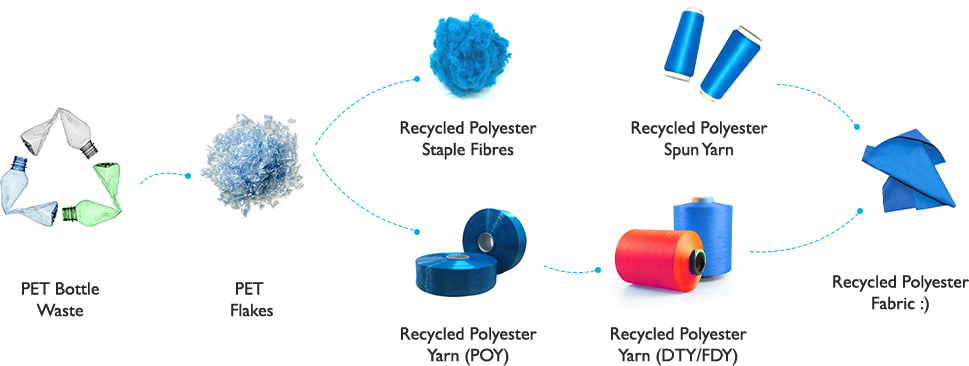

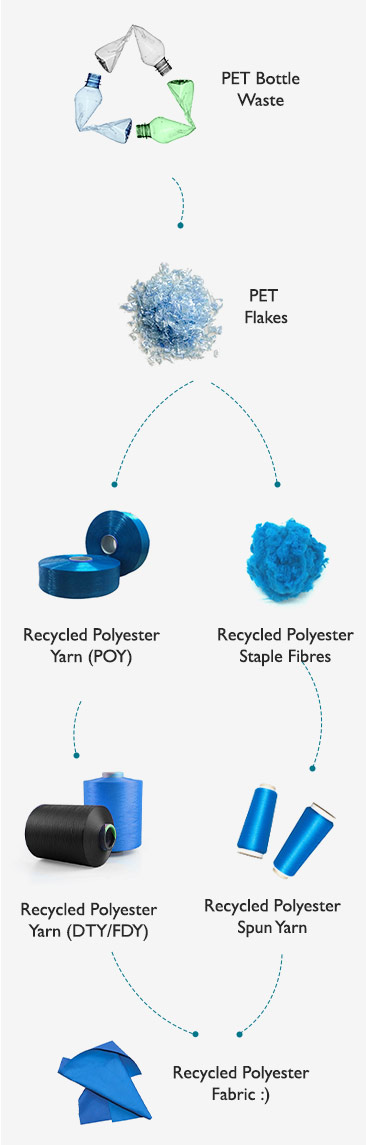

Greenfil®: Recycle for better Tomorrow

Greenfil® is a sustainable brand that processes PET waste into recycled polyester. This

process minimizes the loss of useful resources by converting disposed PET bottles into

flakes, which are then transformed into fibre or filament of various deniers.

Instead of being incinerated or dumped into landfills or oceans, these PET bottles are

repurposed. The resulting 100% recycled polyester fibres perform just like virgin

polyester, making them an eco-friendly yet high-performance alternative.

The Greenfil Way

HNR Recycling UK LTD's sustainable process to convert PET waste into high-performance recycled polyester products.

Zero Liquid Discharge

We all know that water is life, yet tons of it are wasted daily by industries and

households. At HRN Recycling UK LTD, we stand by the Go Green

initiative as a responsible and sustainable RPSF (Recycled Polyester Staple Fiber)

manufacturer.

We’ve installed an advanced effluent treatment plant equipped with the latest

technologies, allowing us to process and reuse all wastewater generated during

production. This ensures there is absolutely no liquid discharge from

our recycling processes.

With our Zero Water Discharge methodology, HRN Recycling UK LTD is a

certified Zero Liquid Discharge unit, significantly reducing water requirements and

helping conserve vital environmental resources for future generations—an initiative

aligned with becoming a leading EPR (Extended Producer Responsibility) service provider

in India.

Renewable Energy

At HRN Recycling UK LTD, we believe in sustainable development—meeting

present needs without compromising the needs of future generations.

We have installed 2.1 MW of wind turbines and a 1.2 MW solar power plant. Additionally,

we have a power purchase agreement with a third-party renewable energy generator. In

total, around 25% of our power needs are fulfilled through renewable

sources, significantly lowering our carbon footprint.

While being a major rPET flakes producer, we also focus on PET fibre recycling across

the globe in a structured and responsible manner. We are proud to be part of the green

movement and continue investing in renewable energy for a better planet.